Turcite® B is the traditional bearing material used on machine tool ways, transfer lines or any linear movement application in which reduced friction and wear resistance are critical design considerations. Turcite® B Slydway increases accuracy, reduces damage caused by mechanical breakdowns and lubrication failures, extends the useful life of mechanical components, saves energy and improves stick-slip performance.

Technical Specifications

| Tensile strength at break | 2,000 PSI |

| Elongation at break | 170% |

| Working temp range | -360°F to 500°F |

| Linear coefficient of thermal expression | 6.0/in/(in*F)*10-6 |

| Coefficient of friction (dynamic lubrication) | 0.02 to 0.05 |

| Specific gravity | 3.1 |

| Water absorption | 0% |

| Color | Blue/Green |

| Color of etched side | Brown/Black |

Calculate the Amount

of Turcite Needed:

Turcite® B Slydway®

Standard Widths: 5/64″ is 12″ and all other thicknesses are 24″

Standard Thicknesses: 1/64″, 1/32″, 3/64″, 1/16″, 5/64″, 3/32″, 1/18″, 3/16″

Turcite Products

| STOCK NUMBER | THICKNESS | AVAILABILITY |

| SW015-24 | 1/64" | STOCK |

| SW032-24 | 1/32" | STOCK |

| SW045-24 | 3/64" | STOCK |

| SW063-24 | 1/16" | STOCK |

| SW078-24 | 5/64" | STOCK |

| SW093-12 | 3/32" | STOCK |

| SW125-24 | 1/8" | STOCK |

| SW187-24 | 3/16" | STOCK |

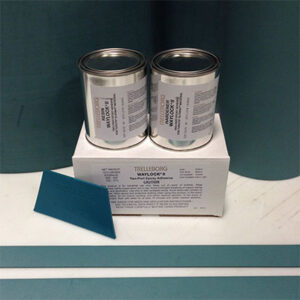

Waylock II – Quart – Stock

Turcite® B Slydway® Advantages:

Extruded Billet Process – reduces internal stresses and allows Turcite Slydway to lie flat for easier handling

Superior Etched Surface – promotes easier, more reliable installation with superior adhesion

Excellent Vibration Dampening – dampens cutting tool vibration from migrating throughout the machine tool

Increased Positional Accuracy – lower friction increases positional accuracy and repeatability on linear ways

Chemical Resistance – resists aggressive coolants and lubricants

High Water Resistance – will not absorb moisture

Low Friction in the Event of Dry Operation – protects mechanical components in cases of poor or failed lubrication

Turcite® B comes in 12″ and 24″ Wide Rolls or we will custom cut to your specifications.

Turcite® B Slydway® System is a complete line of bearing materials along with surface preparation and adhesive products specifically engineered to install Turcite® B Slydway® materials.

We also offer complete line of accessories for applying and maintaining Turcite® B Slydway®.

We also offer complete line of accessories for applying and maintaining Turcite® B Slydway®.

Waylock® II

Trelleborg sealing solutions has specifically developed an effective bearing element between sliding metal surfaces. They are used in linear bearing applications. When used together, Waylock® II and Turcite® B, will provide an extremely reliable linear bearing surface, lower friction, and low wear between sliding metal surfaces.

In the kit:

1 Resin

1 Hardener

1 Serrated scraper

Instructions