Power Scrapers – Superior scraping speed and accuracy, while reducing operator fatigue. Great for OEM remanufacturing and MRO applications on cast steel, hard cast iron, malleable cast iron, nonferrous materials and more. Available in electronic and airdrive models.

• Many times faster and more accurate than hand scraping

• Great for OEM remanufacturing and MRO applications

• Quick and easy to use – reduces operator fatigue

• Adapts to individual operator techniques

• Use on cast steel, hard cast iron, malleable cast iron, nonferrous materials and more

Five unique scraper models are available to suit your specific needs:

7ESM/BS-40 Heavy-duty, variable-speed electric scraper

Scraping Speed, electronically variable: Up to 1900 strokes/minute

Length of Stroke, infinitely variable: 0″ to 0.8″ (0 to 20mm)

Operating Voltage, Standard: 110 VAC, 60Hz (220 V available)

Power Draw: 320 watts

Weight: 11.5 lbs. (5.2kg)

Dimensions: 4.4″ x 2.6″ x 17.4″ (110 x 65 x 440mm)

Applications: Heavy roughing and work on large machines and equipment. Scraping of hardened steel guide ways. Large turbine housings, drives, pumps, valves. Extension handle included.

7ELM/BL-40 All-purpose, medium-weight, variable-speed electric scraper

Scraping Speed, electronically variable: Up to 1900 strokes/minute

Length of Stroke, infinitely variable: 0″ to 0.8″ (0 to 20mm)

Operating Voltage, Standard: 110 VAC, 60Hz (220 V available)

Power Draw: 320 watts

Weight: 9.3 lbs. (4.2kg)

Dimensions: 4.4″ x 2.6″ x 17.4″ (110 x 65 x 440mm)

Applications: Specially designed for Scraping Technique 40. Roughing, semifinish and finish scraping. Oil-tight or steam-tight scraping. Dovetail and Vee-way scraping. Uprights, cross-rails and harder-to-reach areas. Machine tool maintenance and repair. Our all-purpose workhorse for medium to larger work.

BL-10 All-purpose, lightweight, variable-speed electric scraper

Scraping Speed, electronically variable: Up to 1900 strokes/minute

Length of Stroke, infinitely variable: 0″ to 0.4″ (0 to 10mm)

Operating Voltage, Standard: 110 VAC, 60Hz (220 V available)

Power Draw: 320 watts

Weight: 7 lbs. (3.3kg)

Dimensions: 4.4″ x 2.6″ x 12.6″ (110 x 65 x 320mm)

Applications: The ideal scraper for square, Vee and dovetail ways. Highest-quality bearing points and finish on surface plates and master plates. Lightweight and compact design makes this model particularly suitable for finish scraping of cast steel, cast iron, brass and way-liner material. Our all-purpose model for medium to smaller work.

7DLM All-purpose, single-speed pneumatic scraper*

Scraping Speed, electronically variable: 1400 strokes/minute

Length of Stroke, infinitely variable: 0″ to 0.8″ (0 to 20mm)

Operating Voltage, Standard: 110 VAC, 60Hz (220 V available)

Power Draw: 320 watts

Weight: 8 lbs. (3.6kg)

Dimensions: 4.4″ x 2.6″ x 16.8″ (110 x 65 x 425mm)

Hose Connection: 3/8″ pipe thread

Applications: Used on applications where pneumatic power is desired or necessary (danger of explosion). Same applications as the 7ELM/BL-40 model. Single stroke speed. Often used for special applications in chemical, plastics and food industries to scrape off hardened resin or coating residue, etc. Muffler/air silencer not included. * Available on request.

HM-10 Half-moon pattern, variable-speed electric model

Scraping Speed, electronically variable: Up to 1900 strokes/minute

Length of Stroke, infinitely variable: Fixed

Pattern Size (Depends on blade): Small, Medium, Large, Extra Large

Operating Voltage, Standard: 110 VAC, 60Hz (220 V available)

Power Draw: 320 watts

Weight: 6.2 lbs. (2.8kg)

Dimensions: 4.4″ x 2.6″ x 12.6″ (110 x 65 x 320mm)

Applications: Scraping of half-moon oil-pocket patterns for slide way lubrication, or to break up friction and “stick-slip” on precision-machined flat surfaces and ways. Pattern creates pleasing appearance and ensures good surface lubrication with better wear characteristics. Rescraping of worn ways to reestablish lubrication and prevent further wear. Our “Flaker” or “Spotter” model.

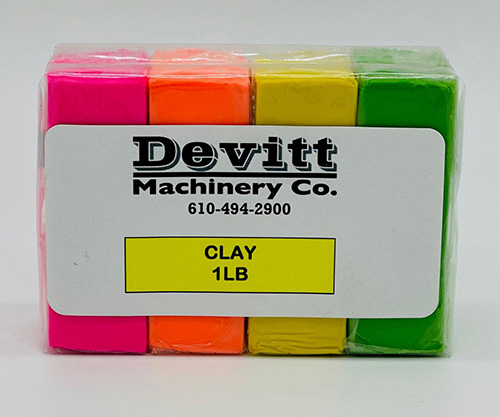

Clay is a smooth, pliable, non-hardening product that is good for adhesion for damming and making reservoirs when using fluid Moglice® products.

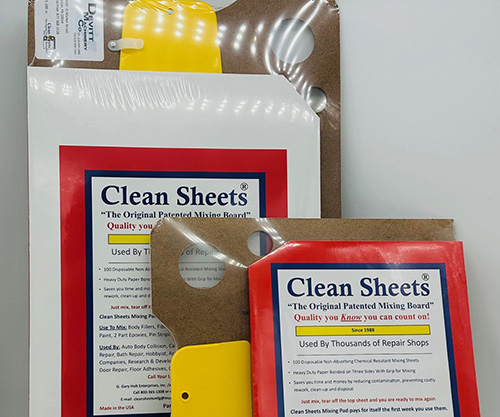

Clean sheets give you a contamination free surface for each new mix!

3 easy steps to follow:

1. Mix on the sheet

2. Apply to surface

3. Tear off sheet for the next mix.

Our Cleaner/Degreaser is an aerosol spray. Used to remove oils and grease from many different surfaces. Mostly used on metal surfaces and Turcite® B, as shown in this video. We use this to make sure there is no contamination stopping any products from adhering to the surface. This is very effective when used properly!

Hi-Spot Blue – Identify high spots, interference points and improper fit on bearings, gears, and valves. Apply this paste, also known as “engineer’s blue”, to part and assemble them into working positions. Any improper fit will show up as a blue streak.

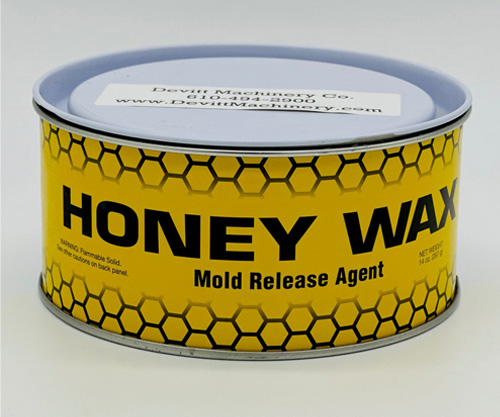

Honey Wax is a unique, high gloss paste wax for use by composite fabricators as a mold release agent. It is compounded with the purest grade carnauba wax, plus special binders and spreading agents.

Injection Syringe/Cartridge – Available in 3 sizes, 100gr., 250gr., and 500gr. Used for injection of fluid Moglice.

Injection Syringe/Cartridge – Available in 3 sizes, 100gr., 250gr., and 500gr. Used for injection of fluid Moglice.

Jiffy Mixers – Specialty designed mixers to reduce air inclusion when mechanically mixing polymers.

Alignment Materials “Moglice Shims” – One square inch shim available in the following sizes: .029″, .040″, .055″, .072″, .092″, .120″, .143″, .032″, .045″, .063″, .081″, .108″, .127″, .185″.

Spatula – Spatula for mixing products.

Spray Bottle – Chemically resistant 24 oz spray bottle.

Teflon Tape

4 Sizes available

3/8” x .020 x 5 yds

¼” x .020 x 5 yds

3/8” x .030 x 5 yds

½: x 0.50 x 5 yds