DWH

Find the right product solutions

Find the right product solutions

“Moulding in place“ is the secret behind innovative machine production and engineering.

DWH adjusts the traverse beam 100% precise and forcefit to the two vertical columns. For this, the traverse was exactly aligned leaving a 2mm gap to fill with DIAMANT Fine Adjustment Coating DWH 310 FL .

Typical Applications

• all kinds of machine tools

• joints, grinding spindles, keyways

• guideways, bearing supports and flanges

• machine beds – bearings and bushings

Product Properties:

• very high precision true to measurement

• high bearing forces up to 120 N/mm2 (static)

• excellent damping and 100% forcefit

• 100% force transfer,

• excellent adhesion

• nearly no aging or weathering

• perfect exactness to the micron

• without costly machining or final working

Product Description

DWH is a fine adjustment coating system for connecting surfaces in machine elements and machine tools, omitting the expensive machining by the proven moulding technology.

Benefits

DWH moulds micron-exact in place making an exact copy of the surfaces they easy way.

The user can decide whether he wants a firm adhesion or a separated one that can easily be dismantled when necessary for this DIAMANT is applied before moulding.

Center, adjust, fix and optimize … are further fields of application for DWH.

• guide pins and bushings are molded in place

• optimizing the stiffness

• screw holes are closed

• machine elements are centered

• element groups are fixed

All that without machining…

… and in 1 step with best damping properties and high cost savings guaranteed by the DIAMANT Fine Adjustment Coating System DWH for more than 5 decades, and not only in machine engineering.

DWH can be used for all metal elements which need to be longterm exact and resistant adjusted, fixed & centered and they improve additionally … the stiffness.

Guide elements are fixed inexpensively without mechanical machining highly precise, guide bushes and/or guide pins are molded in place improving the dampening, too.

More Benefits:

DWH can be used in place without special knowledge for any type of machine element.

And it is that easy:

1. roughen & clean adhesion surfaces

2. align

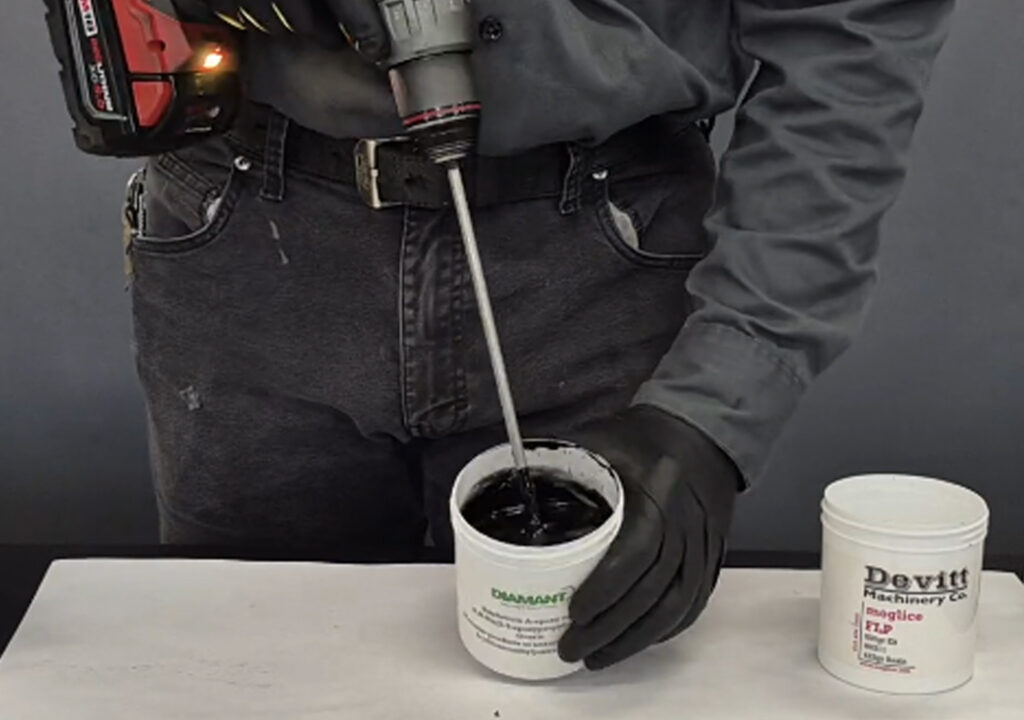

3. mix DWH

4. apply or inject

5. leave to cure and…

6. ready! exact to the micron.

Full DWH Product List Here

DWH 310 FL is a low-viscosity 2-component fine adjustment and adhesive coating based on epoxy resin with steel fillers. This is used for the form- and force-fitting filling and bonding of separating joints to components, assemblies, and components of a wide variety of material components. By means of casting, injection and molding, complex shapes and structures can also be created with a precision in the μm range. DWH 310 FL can be detached by using a micro-thin layer of Diamant release agent on the counter surface. The result is an exact copy of the molded surface. Highprecision preparation of surfaces and mechanical post-processing of the surfaces are not required.

In modern production technology, process times and costs can be reduced many times over.

Form- and force-fitting installation of guides in mechanical engineering

Adjusting coating for assemblies and elements of various materials.

Full-surface lining of moldings and elements as a replacement for feed plates.

Load-bearing gap compensation on beams of portal milling and Gantry systems

μm- precise molding of bushes, centering and guide elements

Fixing and / or centering of bearing bushes according to high precision alignment

As filling and composite material in 3D printing + additive Manufacturing

Safety Data Sheets:

Hardener

SDS DWH 310FL Resin

DWH 311FL

DWH 311 P is a high-viscosity two component adjustment and adhesive coating on epoxyresin basis with aluminum fillers, designed for form- and force fitting filling and gluing of joints on components, assemblies of different materials. Due to spatula- and molding

techniques it is possible to even achieve precision in μm-range. When using a micro-thin layer of Diamant-parting agent on the counter surface DWH 311 P can be separated from it. The result is an exact copy of the molded surface. A high-precision preparation of surfaces and the mechanical post-processing of the surfaces is not necessary. In modern production processing times and costs can be dramatically reduced.

Form- and force-fitting installation of guides in mechanical engineering

Adjusting coating for assemblies and elements of various materials.

Full-surface lining of moldings and elements as a replacement for feed plates.

Load-bearing gap compensation on beams of portal milling and Gantry systems

μm-accurate adjustment of bushes, centering and guide elements

Fixing and / or centering of bearing bushes according to high precision alignment

As filling and composite material in 3D printing + additive manufacturing

Very high accuracy, μm-accurate molding

Very high compressive strength

Extreme dimensional stability after curing

Excellent load transfer due to complete contact of the surfaces

Temperature resistance up to +80 °C

Excellent damping properties thanks to the E-module ca. 8600 N/mm²

Aluminum-grey color after curing

High resistance to oils, cooling emulsions, mineral and synthetic coolants and lubricates and many other chemicals.

Safety Data Sheets:

Hardener

DWH 311P Resin

DWH 311P

DWH 311 FL is a low-viscosity 2-component fine adjustment and adhesive coating based on epoxy resin with aluminum fillers. This is used for the form- and force-fitting filling and bonding of separating joints to components, assemblies, and components of a wide variety of material components. By means of casting, injection and molding, complex shapes and structures can also be created with a precision in the μm range. DWH 311 FL can be detached by using a micro-thin layer of Diamant release agent on the counter surface. The result is an exact copy of the molded surface. High-precision preparation of surfaces and

mechanical post-processing of the surfaces are not required. In modern production technology, process times and costs can be reduced many times over.

Form- and force-fitting installation of guides in mechanical engineering

Adjusting coating for assemblies and elements of various materials.

Full-surface lining of moldings and elements as a replacement for feed plates.

Load-bearing gap compensation on beams of portal milling and Gantry systems

μm- precise molding of bushes, centering and guide elements

Fixing and / or centering of bearing bushes according to high precision alignment

As filling and composite material in 3D printing + additive Manufacturing

Very high accuracy, μm-precision molding

Very high compressive strength

Extreme dimensional stability after curing

Excellent load transfer due to complete contact surfaces

Temperature resistance up to +80°C

Excellent damping properties due to the E-module ca. 8700 N/mm2 steel grey shade after curing

High resistance against cooling emulsions, mineral and synthetical coolants, lubricants and cutting materials

Safety Data Sheets:

Hardener

DWH 311FL Resin

DWH 311FL

DWH 316 P is a putty precision alignment system for joint faces in machines and machine tools which reduces machining by using the molding technique. These technique allows an in-place molding to precision down to the micron with an exact replica of the tool surface.

The material can be either caused to stick to the molding surfaces or released by the inclusion of a micro thin layer of release agent.

All type of gantry machines

Joints, spindle shafts, key slots

Guide rails, bearing chairs and flanges, machine beds

Bearing and index bushes

High Accuracy

High load carrying capacity [160 N/mm²]

Excellent shock attenuation

Full contact of mating surfaces and therefore good transmittal load

High damping capacity

Good adhesion with nearly zero aging

Precision down to the micron without expensive machining or finishing work

Safety Data Sheets:

Hardener

DWH 316 Resin

DWH 316 Putty

Example: 48″ Length x 5″ Width x .062″ Thickness = 14.88 cubic inches x 31 (FL) = 461 Grams of DWH Needed

Click the button below to download the Machine Tool Way Rebuilding Handbook. Requires Adobe Acrobat Reader to view.